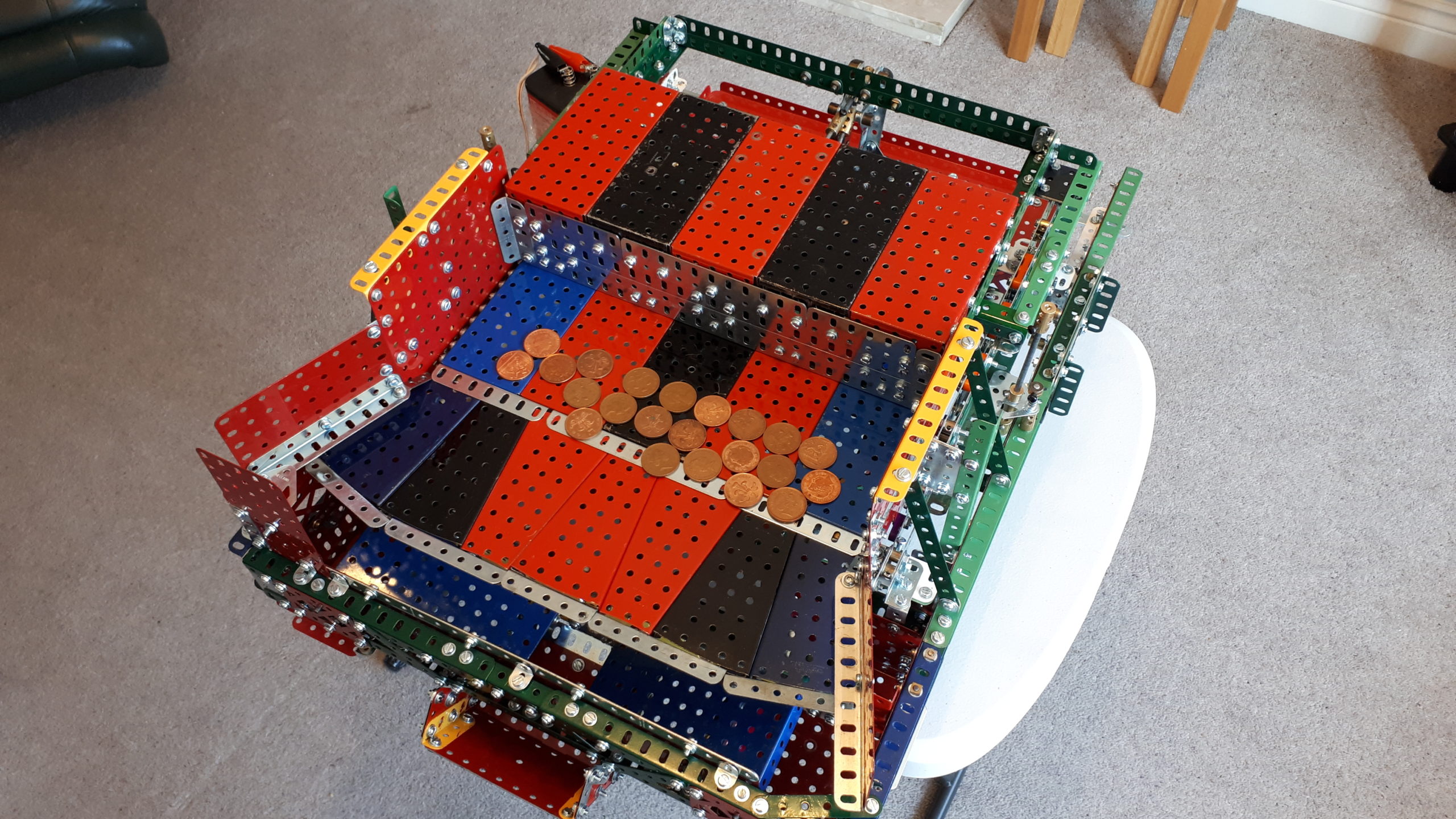

Steve Briancourt: I am building an amusement arcade type "Penny Falls" machine as instructed by my children for use by the grandchildren! This will use 2p coins (when lockdown is over and I can get to a bank to acquire some.)

There are a couple of key features which must be done properly for a successful machine. These are firstly to have a very rigid subframe to avoid deflection as the table runs back and forth, and secondly to have as near as possible frictionless bearings for the table. The upstand above the table for the coin drop is a separate module easily removed.

I had initially intended to use collars (No.59) as roller bearings but this would have necessitated all four runners (in two pairs) being absolutely parallel, otherwise not all rollers would be squarely in contact. Instead I have opted to use Meccano ball bearings set loosely in carriages, which are much more forgiving for the runners being out of true.

There are two carriages per track. The end result is very pleasing with a high load bearing and very low friction table motion. The table itself simply withdraws off the bearings rearwards out of the machine. There are stops on the tracks to limit the movement of the carriages, thus keeping them in the correct location.

Annoyingly, my running clearance between the moving table and the fixed table surface appeared to vary each time I fitted the table. It transpires that Meccano ball bearings vary in nominal diameter by quite a lot, nor are they completely spherical. So now, my carriages are marked to indicate their installed location.

The subframe is supported on three legs to avoid the machine deflecting when placed on an uneven surface.

I was not convinced that a single gearhead motor would have enough oomph to move the table and push a heavy load of coins forward, so the drive module incorporates two motors. The complexity of the gear arrangement is to ensure that if one of the motors fails it will not stall the drive and cause the second motor to burn out. Both motors apply effort via a contrate gear clutch.

The moving table top has been set absolutely flat using a substructure and adjustable supports under each flanged plate. The fixed table top is similarly supported. The flanged sector plates at the front allow for the central one to be angled up slightly. This is a feature of the real machines and encourages the coins to be forced sideways, thus falling into the side pockets of the machine and not to the punter.

You can see a video of this Penny Falls machine on YouTube.

This last photo is showing the very latest progress. On the front left hand side can be seen the side walls and the drop zone for coins entering the machine's vault. All the gaps around the tables, where a coin may have been able to drop through unintentionally, have been blocked off by various means. Controlling the gaps either side and below the moving table is quite crucial as they must be small enough to prevent coins passing through but large enough to provide clearance over the whole range of motion.

Because of lockdown, we are unable to cobble together any more 2 pence coins than those shown here!

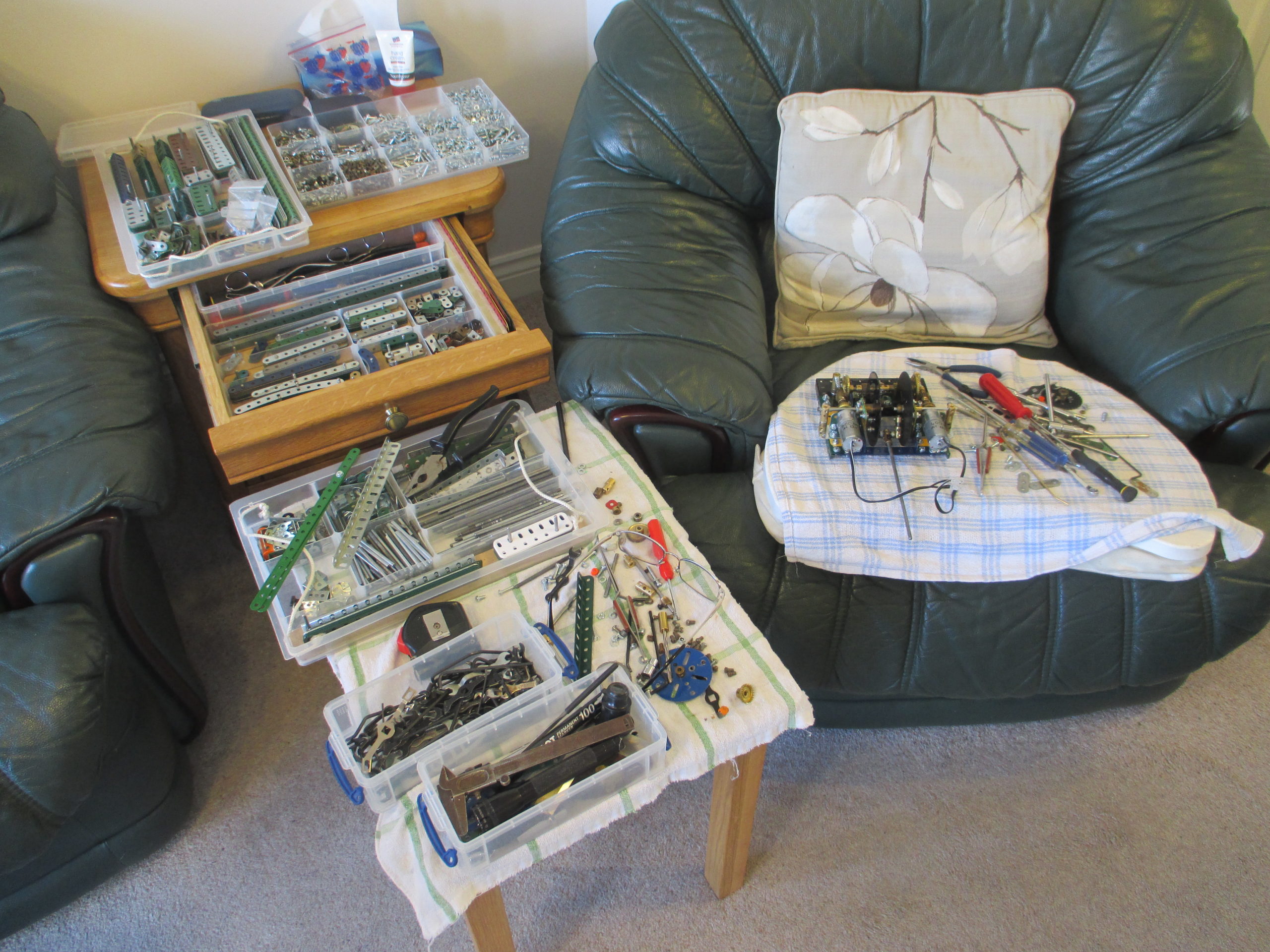

Some of the club are including photos of their Meccano 'dens'. I don't have a bespoke den as such. I do have Meccano storage in a hobbies room but I do my building in the lounge.

Most of my 'ready to use' Meccano is stored neatly in 'Really Useful Boxes'. The boxes have inserts that can be seen in the photo, and pallets with pins to store strips, girders, plates etc.

In the lounge I have a modified oak cabinet to house my immediate build stock. This is replenished as needed from the main storage.

In all, there are ten levels in the cabinet, achieved with 'Really Useful Box' inserts. Because I build in the lounge I suspect my larger models will always be modular to allow them to be worked on and tidied away reasonably quickly.

In one of the upstairs bedrooms I have commandeered part of a wardrobe for Meccano which is not ready to use but awaiting restoration. The garage holds tubs of junk Meccano only suitable for cut downs and prototyping. There are also some modern boxed sets secreted away in some bedrooms "for the grandchildren".

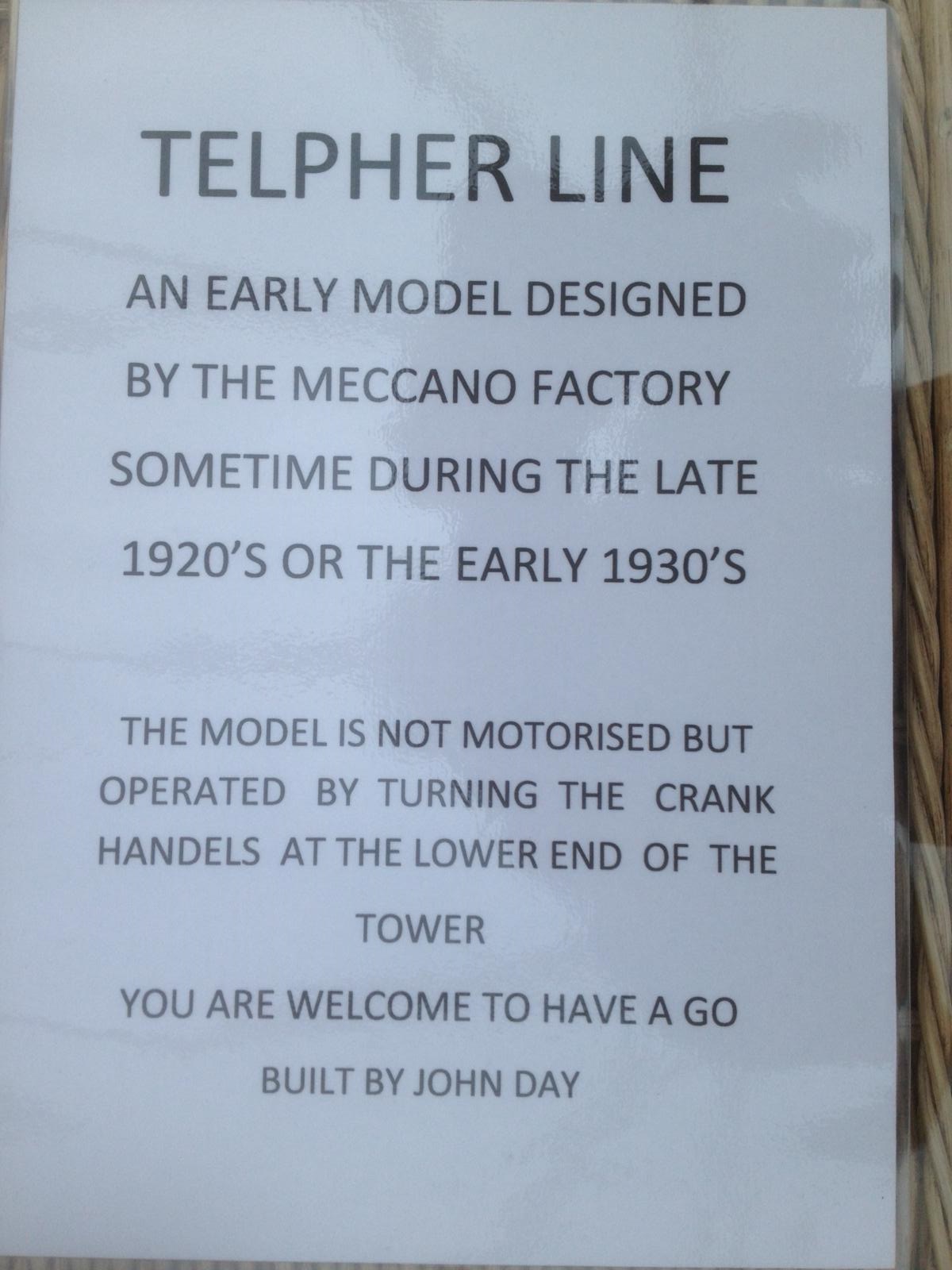

John Day: I am displaying several models:

I have built the Blackpool Tower, a Meccano Magazine 'Model of the Month' from October 1956. The original had a clockwork motor, but I have fitted the PDU motor with auto reverse for demonstration long running.

The Big Wheel is driven by a small motor taken from an old video recorder. And the wheel lifts out of the A frame (without needing tools) for easy transportation.

A video of this can be seen on YouTube.

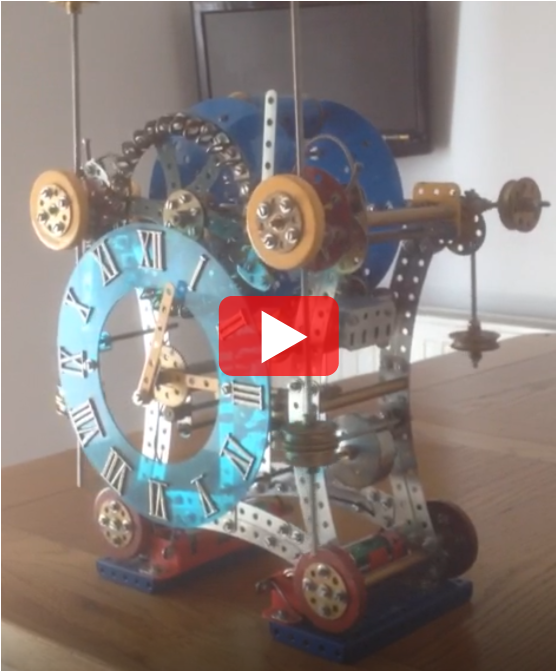

The navigation clock which everyone has seen just keeps going and going and has now been doing so for many weeks if not months

A video of this in action can be seen on YouTube.