Neil Bedford:

What I am working on:

At the last SWMC gathering I showed a ‘boat at sea’ mechanism. The idea is for this to depict the WW2 Operation Frankton (aka ‘The Cockleshell Heroes’) which was a daring Commando raid conducted using kayaks. This one really gripped me at first but I now require some fresh inspiration. This will be one of those models which you can ‘switch on and walk away from’, which can be handy at an exhibition. A short video can be seen on the 2020 February meeting page.

A Ferguson TE20 tractor (‘The Little Grey Fergie’). This one is based on the excellent model built by our own Richard Smith and which is now available as a Model Plan from the MMG. Typically I cannot simply build from the plan (even one which is this good) and have been going off-piste to some extent. The rear wheels of my tractor are a fraction larger than Richard’s which has driven me to re-scale the whole model from images of the prototype. At the moment I have not gone much further than a rolling chassis, incorporating the complex gearbox / rear axle assembly which Richard has designed superbly well. Whereas Richard needed to stick rigidly to standard parts for his Model Plan, I have been able to cheat just a little with some 1/8” face pinions which has been handy. Whilst I am lucky to have a fair bit of very nice Meccano, I am again building from mostly old parts which I have stripped and resprayed. For this model I am using Ford ‘Polar Grey’ car paint which is readily available, is a close match to the original Ferguson grey and does look lovely on Meccano parts.

There are also photos of Neil's Meccano Den in his article Neil's Meccano Year 2019-2020.

Rob Curling:

Unintended Consequences and Back to School Physics

Most members will, by now, have seen my version of the Twin Beam Pumping Engine (Fig. 1) which is based on the Canadian Special Model no. 14 instructions. Rather than describe the whole model in detail I thought that the following recent incident might be of interest to others.

Having spent a considerable amount of time sorting out and solving problems with the Watts linkage I turned to the question of locating and (hopefully) rectifying a noisy gear set which was creating a cyclic grinding noise.

At one point I stood the model on end and was intrigued to see an occasional flash from somewhere near the motor. I eventually tracked this down to a spark jumping between one of the motor mounting screws and the motor mounting plate with a frequency of about once per minute (see video clip).

The motor is made by Buhler and is one of two that I acquired at a toy fair many years ago. It runs at about 5000 rpm when supplied from a 6 volt battery but I regret that I have no further details of its characteristics. It is mounted directly onto a piece of copper coated paxolin board. The fixing holes of the board are oversize and each has a rubber bush (Fig. 2 – Meccano part no. 23c or A623) inserted through which the securing screws are passed to fix it to the model (Fig. 3). This isolates the motor mount from direct mechanical and electrical contact with the structure and is intended to reduce noise and vibration. It is from the head of one of these screws that the spark emanates.

A general view of the drive arrangement is shown at Fig. 4 and a closer view at Fig. 5. In these the motor is rotating clockwise as viewed and it can be seen that one of the driving bands (Meccano parts nos. 186h or A696) passes very close to the exposed screw shank seen between the driving bands.

I can only speculate that I have inadvertently created a miniature Van de Graaff generator and a static electrical charge generated at the driving band/plastic pulley interface is being carried by the band to the screw. Using the rule of thumb that an electrical spark requires a potential difference of 3 Megavolts/metre to jump a gap then my generator is apparently raising the potential of the screw to between 9,000 and 10,000 volts!

Unintended consequences indeed! However, be assured that this does not present any danger to anyone since we are dealing with static charges which are dissipated as soon as the spark appears. In any case the drive arrangement has now been altered and the generator removed.

The noisy gear? Oh yes, that turned out to be a slightly eccentric helical which has now been replaced.

Rob's Restoration Tip

Following on from the last line of the text, at the last meeting I was discussing with Chris the question of correcting the eccentricity in some parts, particularly gears where accurate meshing is desirable. My own method is as follows:

1) Open up the central bore to 3/16ths of an inch.

2) Solder in a short piece of 3/16ths diameter brass rod leaving a small amount protruding at each end.

3) Using whatever means you have to hand (I use a dial gauge and stand) set the part absolutely central in a 4 jaw chuck. (A 3 jaw chuck cannot always be relied upon for absolute centring).

4) Face off one end and bore the workpiece to 4.1 mm.

5) Reverse the workpiece and face off the opposite end.

6) Move the workpiece to a vice, then using the existing tapped hole as a guide, drill and tap the cross bore 5/32inch BSW for the fixing screws. I use a 1/8th inch drill as a tapping drill but this is not critical and any drill up to 3.3mm will give a satisfactory result.

I would be interested to hear how others tackle this problem.

Chris Bates:

My Diddler

Just after Christmas, I suddenly realised that there were less than 5 months before Skegex and I hadn't even thought about the model I would be taking. And worse still, I had no ideas for my next model. I had been concentrating on the Alvis Stalwart army truck which is being serialised in the Sheffield Meccano Guild magazine but that would not be ready until 2021. What to do?

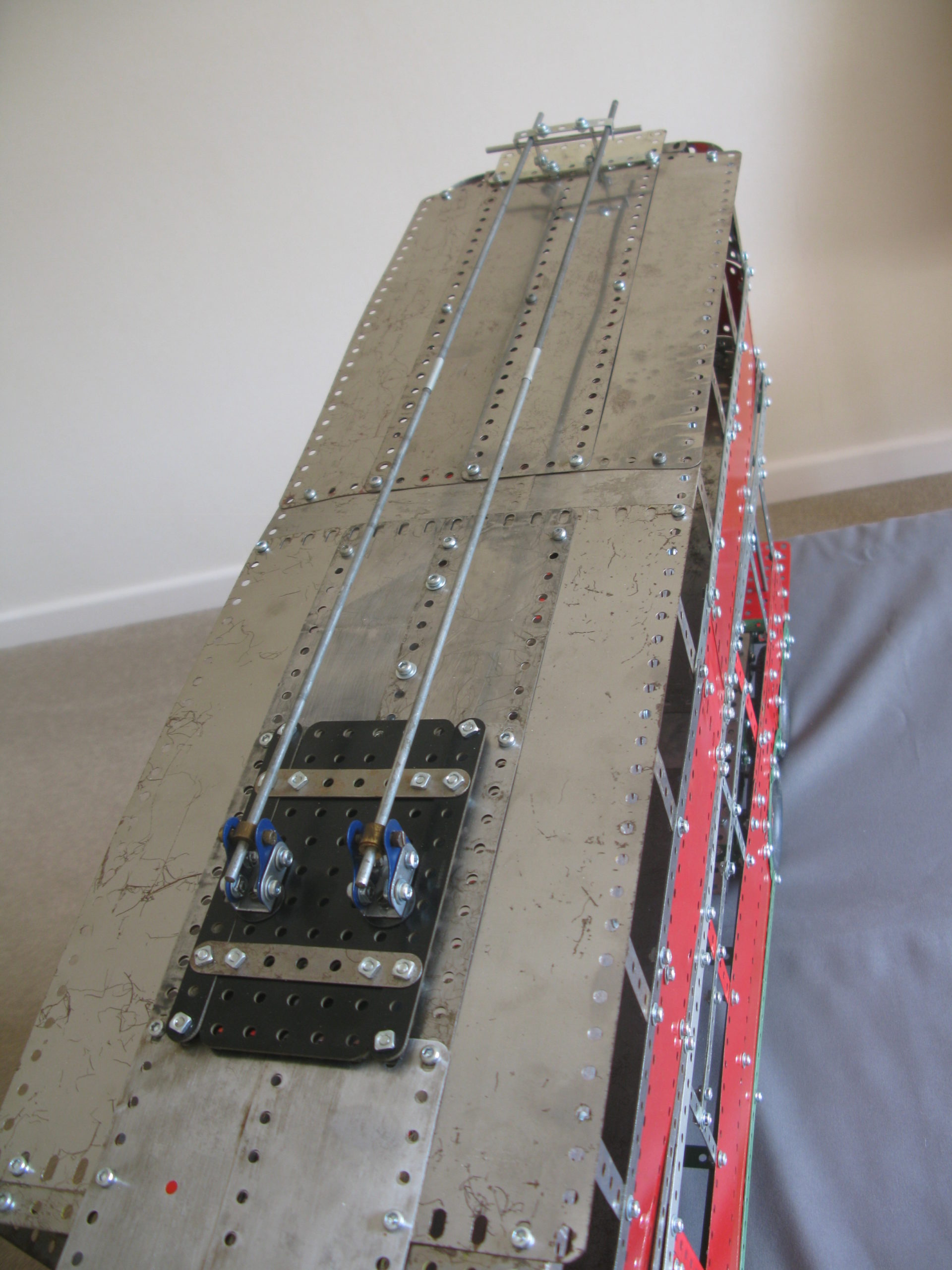

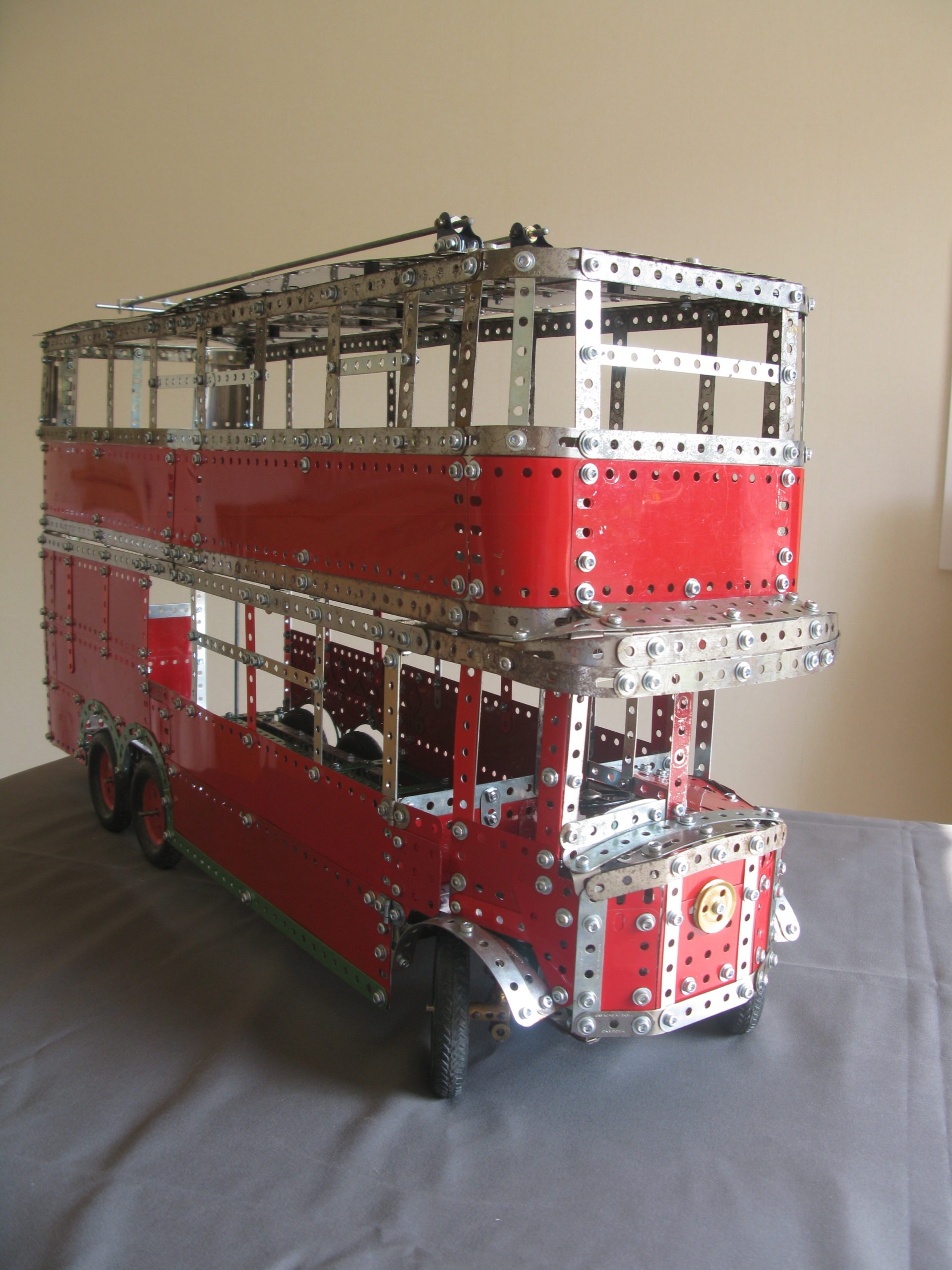

I was trawling through some videos of trams and buses on Youtube and came across one on trolley buses and in particular the first London trolley bus, a "Diddler". It looked like something I could knock up over a few months and so far as I was aware, nobody had done one before! (They probably have though!).

Matchbox did a 1:76 scale model and it was simply a case of increasing the size of that model. I had some non Meccano wheels (maybe Marklin) which were fitted with Dunlop tyres and measured 3½ inches across including the tyres and a little larger than the 3 inches based on Meccano 2 inch wheels and less than the Meccano 3 inch wheel option which would have made it a very large model.

Building up the rough shape of the "Diddler" was relatively straight forward but as I got further into the build, I found I had to make a number of alterations to make other things fit. As with all Meccano scale models, there are inevitably a number of compromises but the bodywork and motorisation is now complete. You will see from the photos that there are as yet no seats nor a staircase to the upper deck and there is also the small matter of a floor for the downstairs saloon! The other main issue is how to access each floor of the model to fit the seats and windows and at the moment it is in two halves with the top half located on to the bottom half using threaded pins into ½ inch brackets.

The electrics should be very straight forward since there is a positive and negative overhead wire which when picked up by the poles makes the wiring a cinch. However, the poles themselves are a major problem which I have yet to resolve since on the original the poles are held against two overhead wires by a pair of springs for each pole and the weight of a 23 inch Meccano rod is way too heavy to be raised by a couple of Meccano springs. At the moment, I am thinking about 4mm aluminium tube.

You will also notice that the model is a mixture of red and unpainted parts. This is because I had intended to paint the model in its two original colours, red and cream but unfortunately, the lockdown meant that I haven't been able to get to a paint suppliers and although I am sure I can buy online, I need to be able to match the cream colour first.

So there you have it. Would I have completed it before Skegex if things had been different? I'd like to think so but it would have been a close call!

This model will now go on the back burner until I can get the paint sorted.

By the way, these trolleybuses were only known as Diddlers by the London Transport staff who operated them. No one knows for sure how the name came about but they were particularly quiet after the trams that they replaced and the only real noise they made was the sound of the trolley poles bouncing over the joins in the overhead wires - a sort of did-did, hence 'Diddler'.

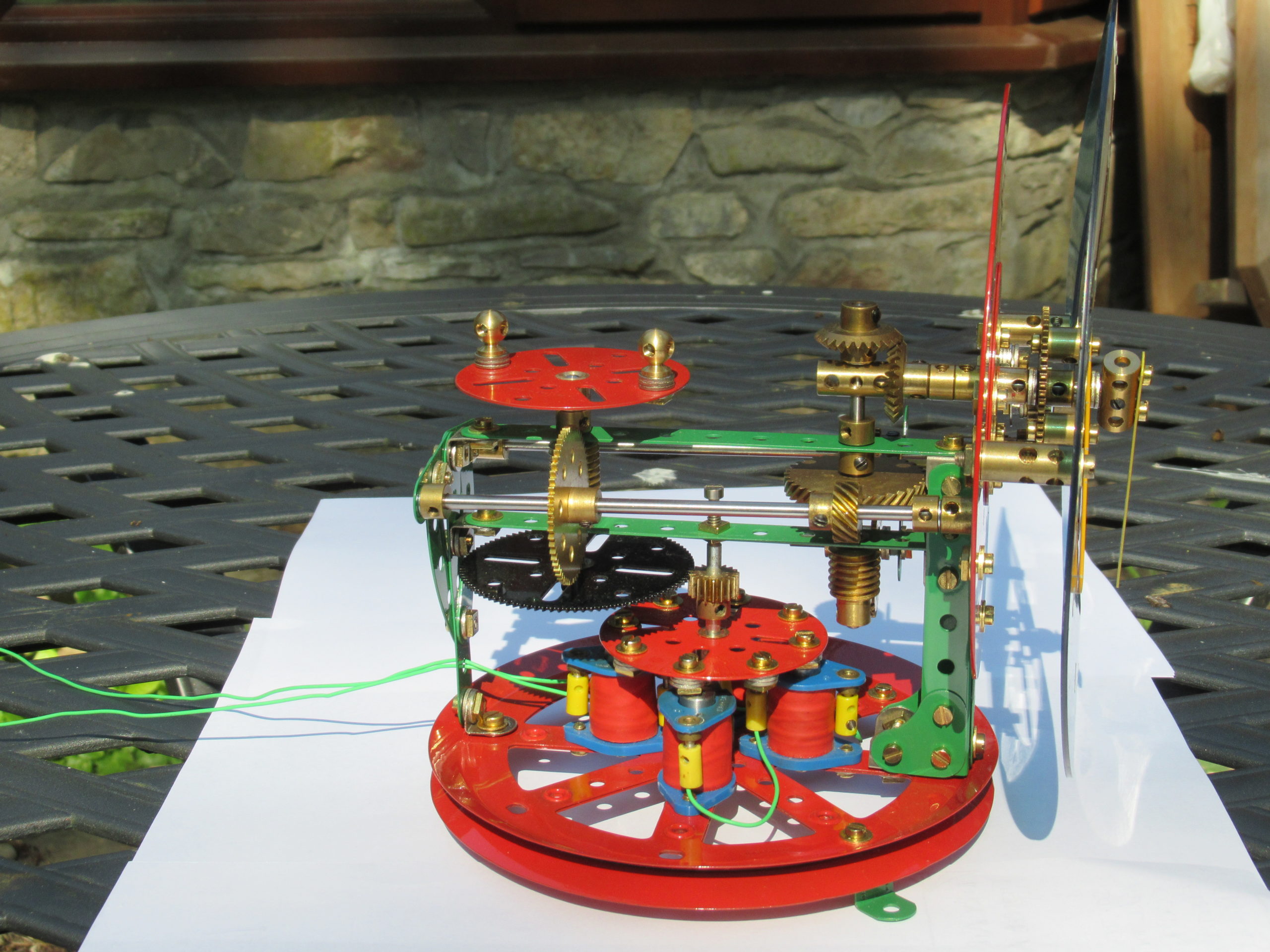

Richard Smith: These are a couple of models I have been building since lockdown. The first is a Konkoly Minute Clock as seen in the latest Runnymede magazine but this model actually has a minute hand (which the Konkoly doesn't have).

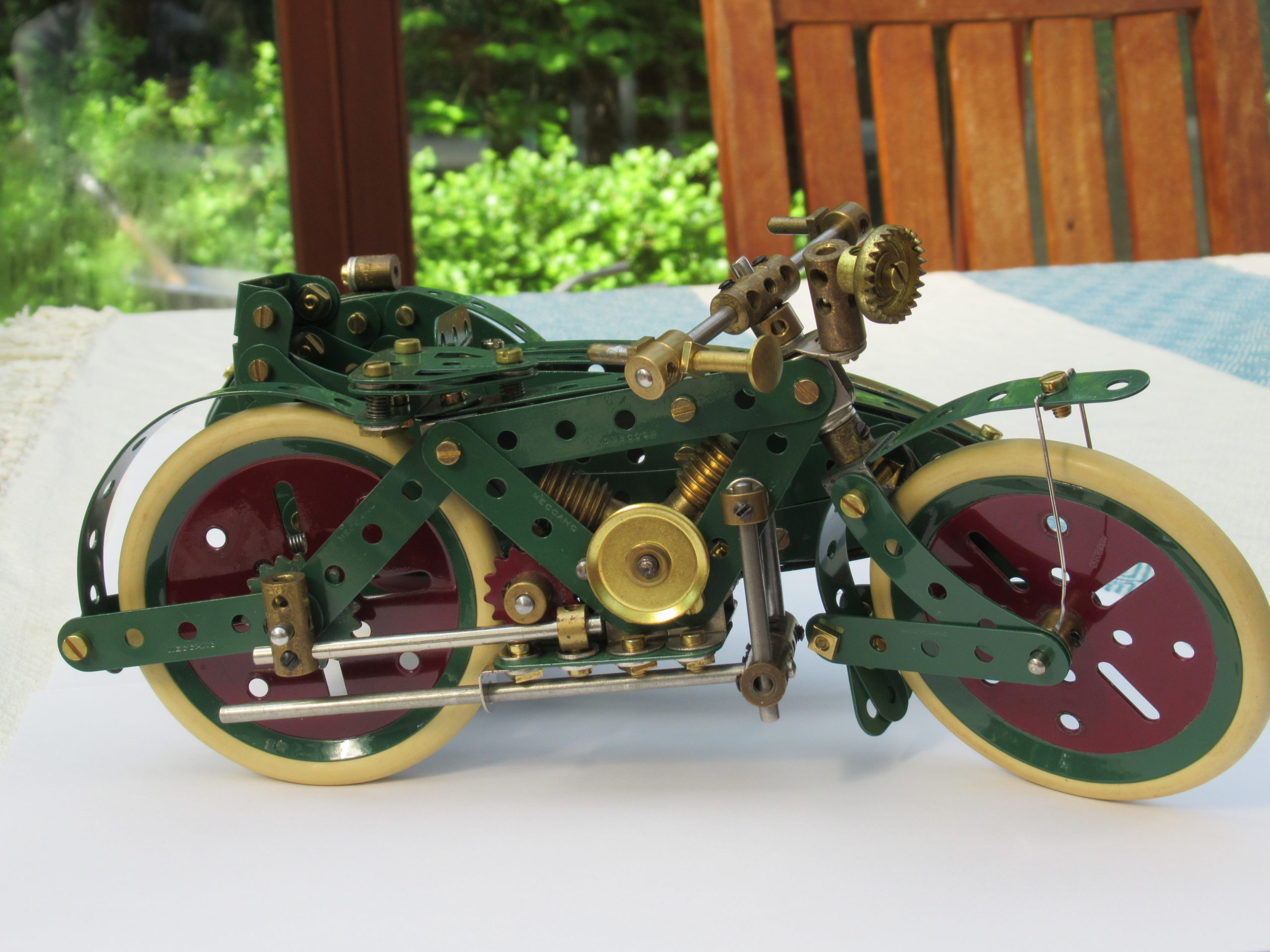

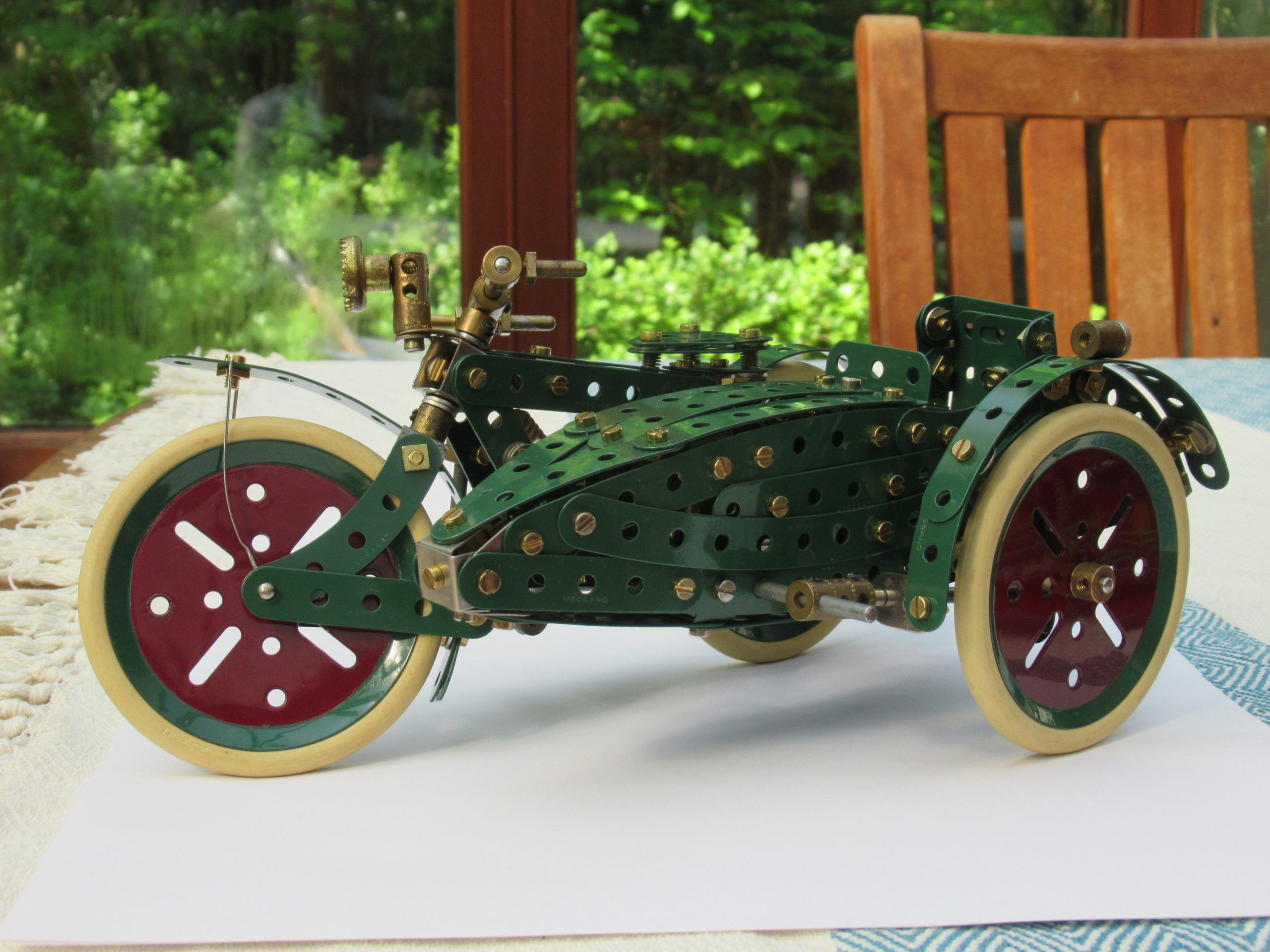

The second model is the Meccano Ltd Super Model Leaflet SLM 3 Motorcycle and Sidecar from 1928. Many modellers have built this but I have incorporated the special wheels from 1928.

A big thanks to all who have contributed articles and shared their models with us for this extraordinary meeting. Sorry there is no cake this time, but hope we can all get together again soon. Dianne.