Our October meeting was a busy one and the day seemed to go too quickly with so much to see and do. Apart from the models to appreciate, we had a sales table (which did incredibly well), a splendid lunch, our AGM and the voting for the two trophies.

Thanks to Dianne and Linda for manning the kitchen and to all those who kindly brought cakes and sandwiches to share.

Sam built a crane using the instructions and contents from the Crane Set which was available 1976 to 1981. This particular model is of a Stothert and Pitt Crane, which utilises the Toplis Level Luffing system. The model also uses the yellow crane motor which is known to be notoriously gutless! A description of the level luffing principle can be read in the photo of Sam's info sheet.

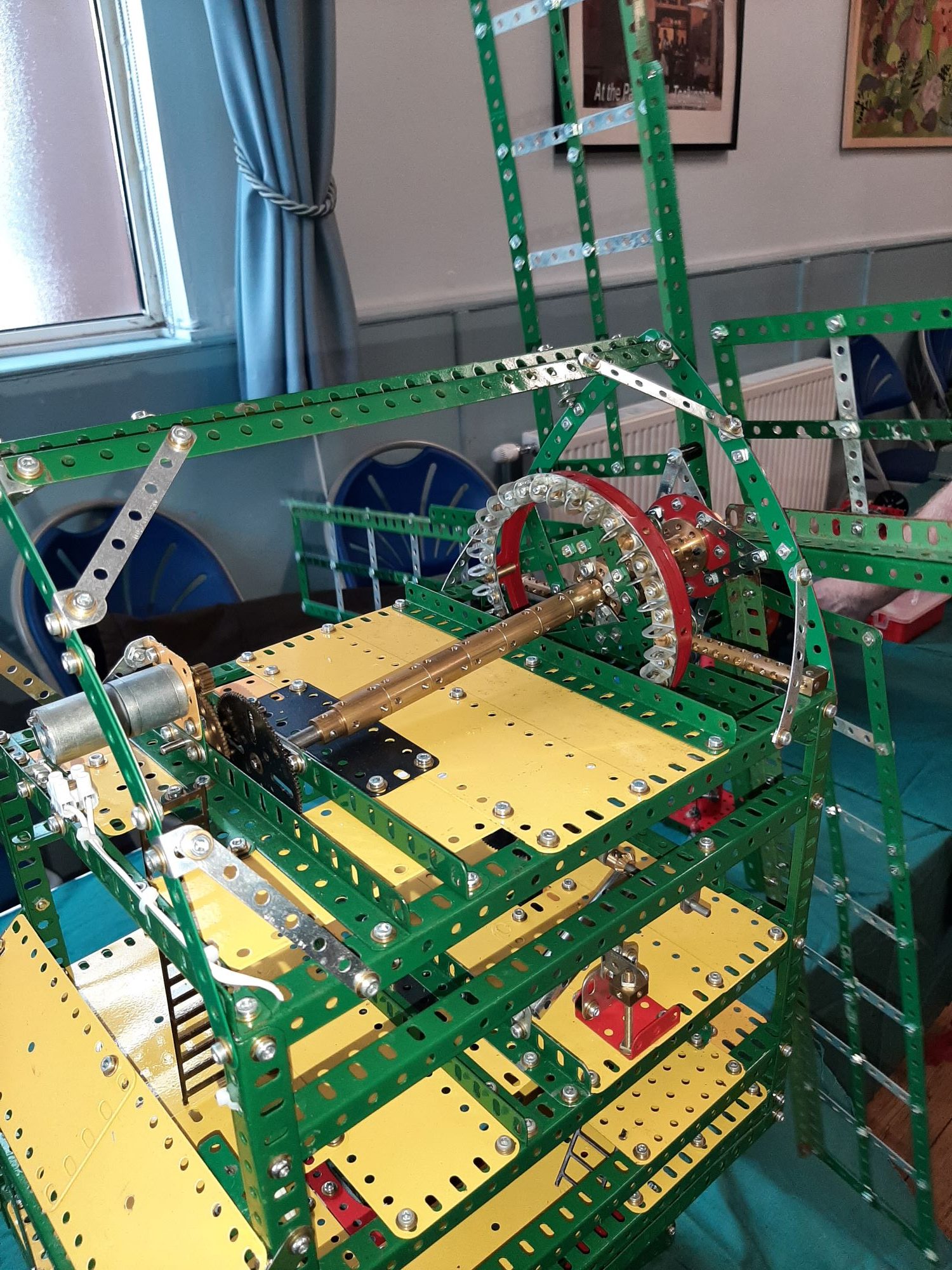

Rob did a sterling job of looking after all the cash transactions but he also brought along an Off Road Racer built from the Radio Control Set 8700 which was sold through Marks and Spencer in the early 2000s.

Using parts beyond the contents of the set Rob had made some additions and alterations to the published Set Manual instructions including:

i) Infill of the large open space behind the seats

ii) Increasing the roof width to 4.5 inches (to match the body width) from 4 inches thus getting rid of the flimsy looking roof supports and also the odd looking upward slope of the roofline from the B pillar to the A pillar.

iii) Generally stiffened the structure by the addition of strips and small flat plates.

Unfortunately, whilst the radio control system still controlled the Forward/Reverse movement of the vehicle, it provided only a very small amount of lock for the steering function.

When time permits Rob intends to make a more conventional chassis and a neighbour has already asked ‘Where is the matching horse box?’

Andy brought two models plus an item of interest. His first model was his version of the tractor 'The Little Grey Fergie' as designed by Richard Smith and published as a model plan. It is still a work in progress and Andy remarked on how ingenious the gearbox is. The model incorporates a rear power lift which raises more slowly than lowering, which is as it should be.

His second was a whimsical model of a man turning a handle to operate a reciprocal saw. It was driven by a Powerdrive motor.

He couldn't bring his huge block setting crane so instead he brought a mini version of it.

He also brought an old E15 motor with the shaft running through a ball race instead of the plain bearing. This considerably reduced the friction and consequent current draw.

Ian's windmill (which can be seen in operation in the previous video) is a model the one in Chinnor in Oxfordshire. There were only two others built like it, standing on six separate stubby pillars, supporting three large timbers (called cross trees). The actual windmill was built in 1789 and sometime later the fan tail was added to automatically align the sails to face the wind. The model reflects this update with a rotating fan tail.

He also had a two storey working lift. It took him a few build attempts to get it working, but the lift cage now moves from one floor to the next with matching opening doors on both cage and the target floor. Interestingly, the mechanism to open the doors is on the cage and when the cage reaches its target floor, the mechanism engages with the floor's door to also open it. In this manner there is only one door opening mechanism required, instead of having a mechanism on every floor. Eventually, this model will be controlled by relays to operate autonomously instead of by the toggle switches seen in the video.

In the past, Barry has seen some Meccano shop display boards showing various Meccano mechanisms in operation. The ones in the photos mounted on black boards were made by him, all fully functional and looking superb. The third photo is a picture of a genuine one.

He also displayed nice examples of a Mechanisms set and a Gears set. These were the sets we wished for as birthday presents when we were kids.

His last item is a clever mechanism he saw and recreated. It turns a driveshaft 90 degrees without the use of gears. You have to see the video to understand how.

Alan's windmill is a smaller version of his previous windmill (half the size). It looks finished but he has tried to motorise it so there may be a little extra to be done. On the close up photos you will notice a long curved strip on the side. He explained that it is actually a standard 25 hole strip which has been bent in its flat plane. We have never seen this done before.

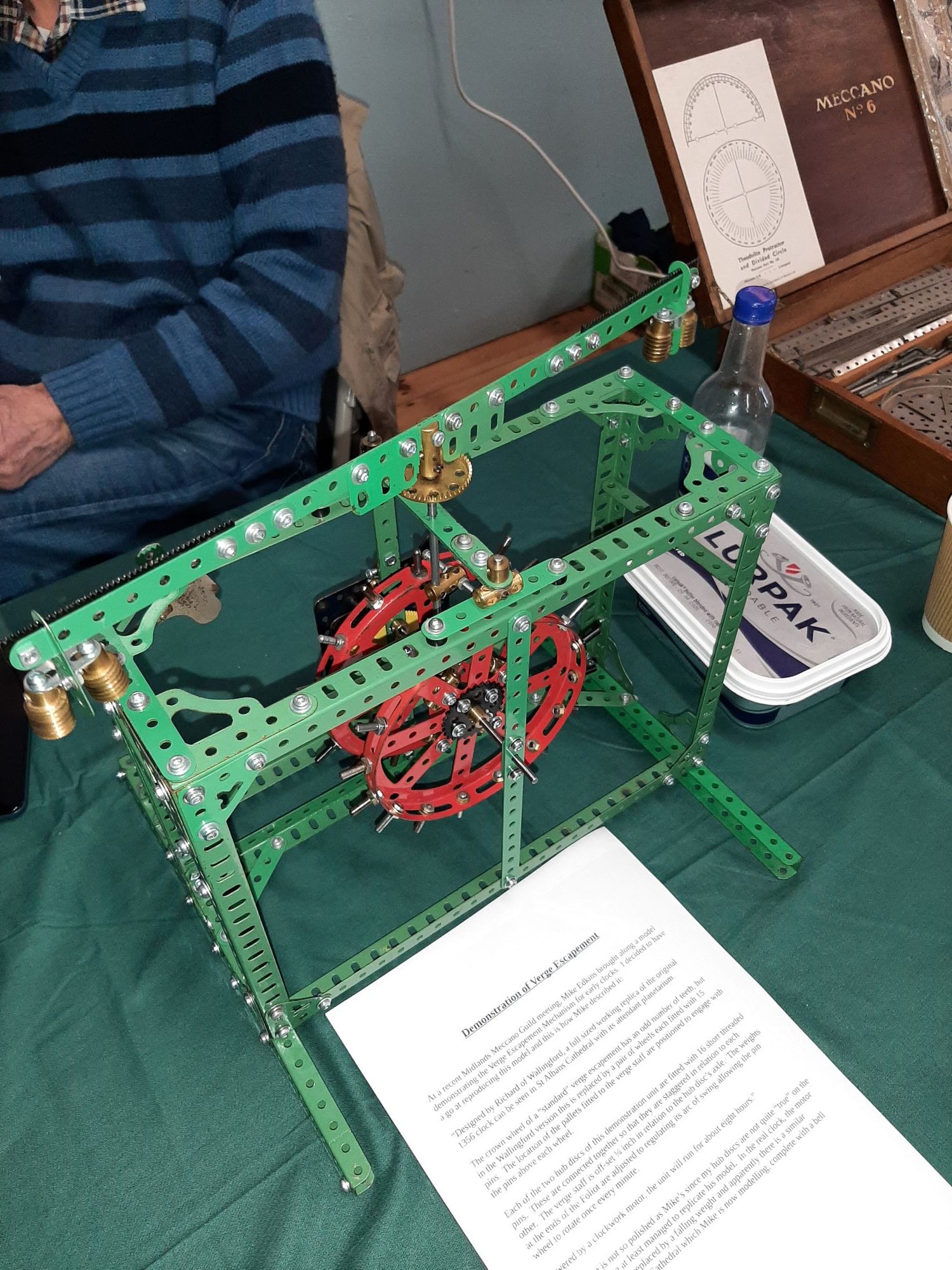

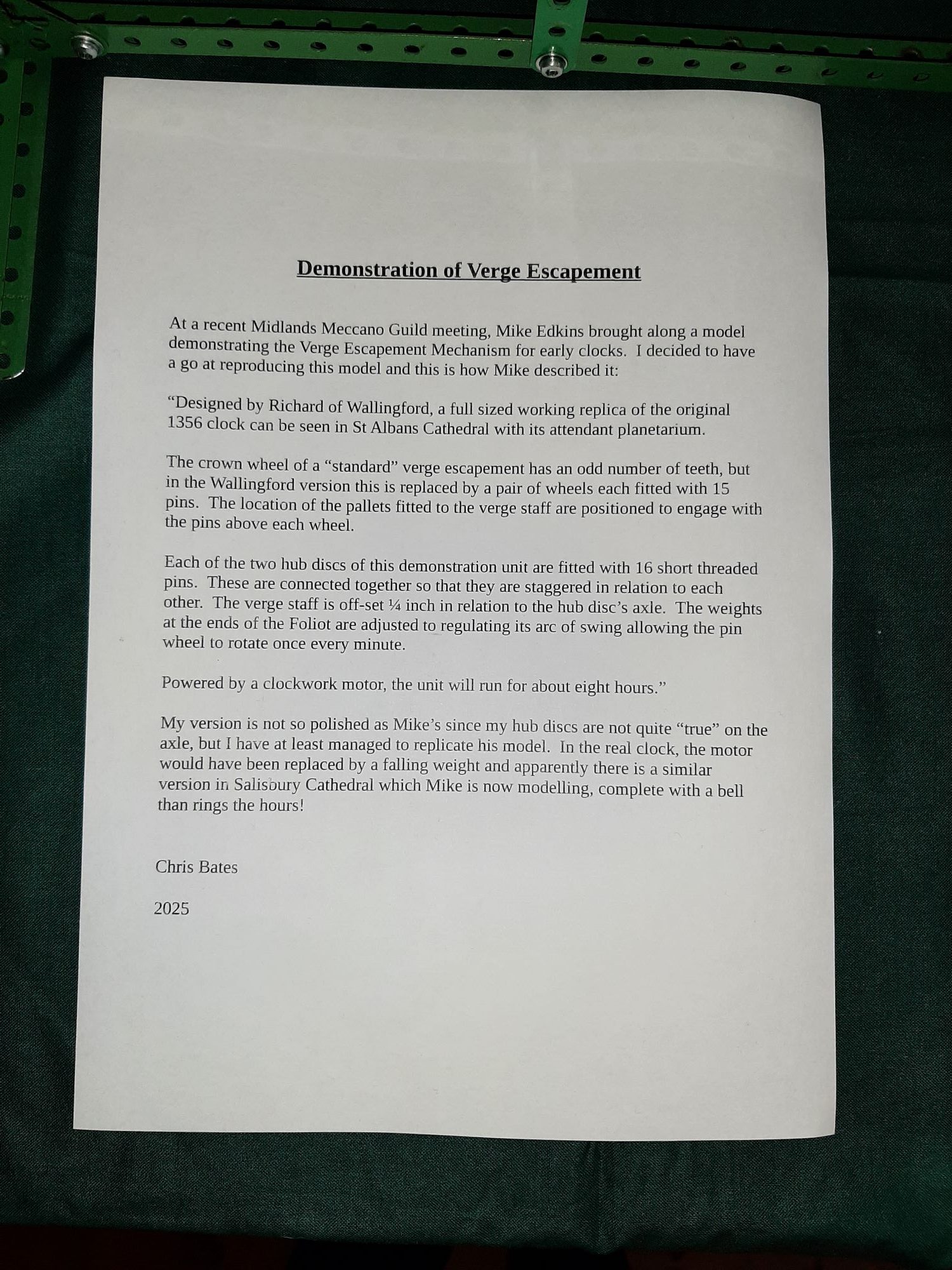

Chris's construction was a 'Demonstration of Verge Escapement'. A full description of this can be read in one of the following photos.

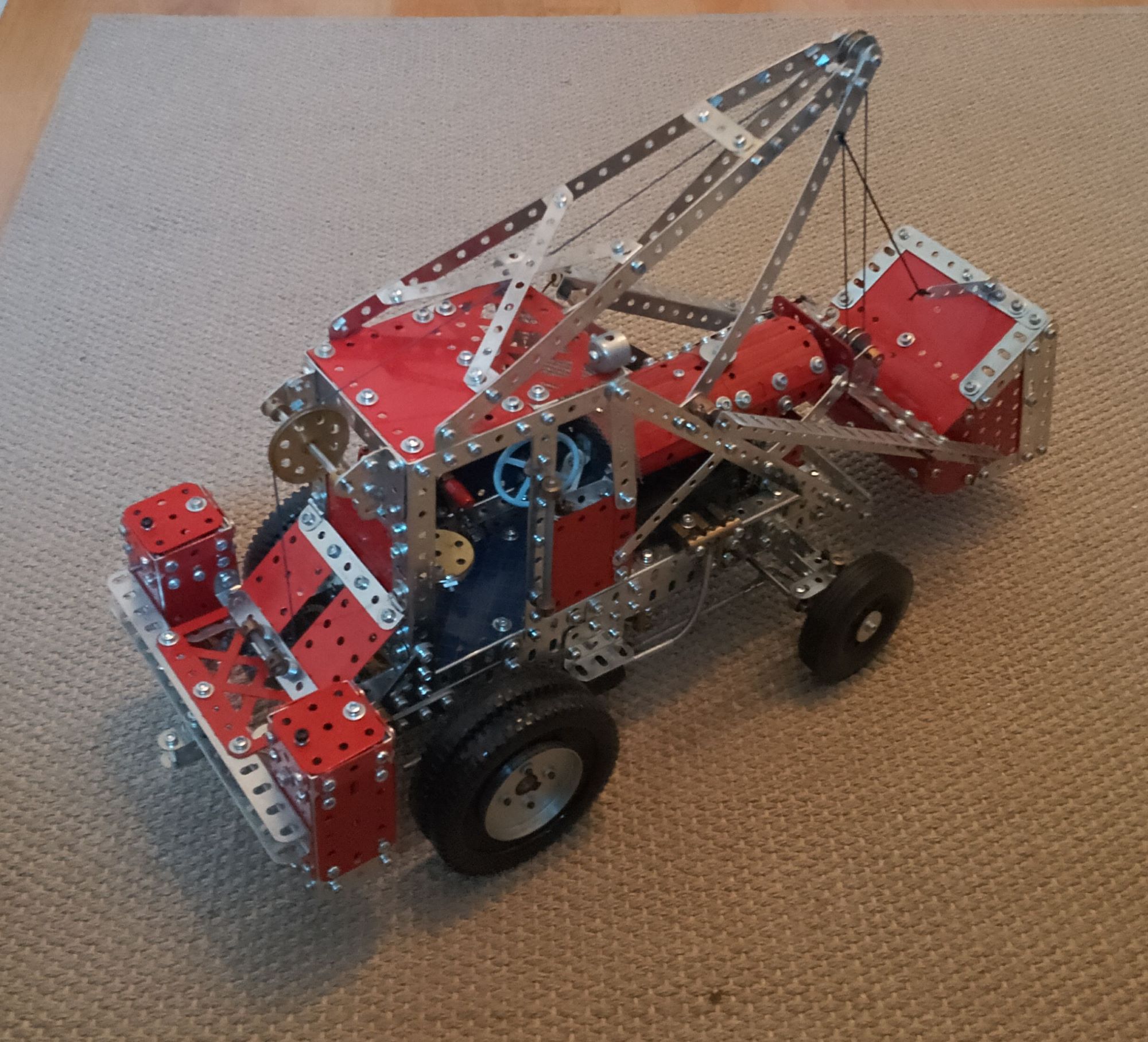

Neil's lifting shovel is from a Set 10 manual which he almost built to plan, as he did improve the steering. Red and Zinc is not a usual combination but it does look smart. The bucket lift is a geared mechanism and all controls are manual. This was built for the 2025 Skegex Challenge which asked modellers to build their own version of this iconic set 10 model.

This won the Malcolm Hanson Trophy for the best model at this October AGM meeting as voted for by all members present.

Richard S brought a work in progress of a gantry crane from the May 1951 Meccano Magazine. The crane's cab can traverse along the gantry, rotate (slew) and the jib can move up and down a little. Driving these functions via a cab which is on the move is done via three shafts along its gantry length, each of which have gears along their length which engage with gears on the underside of the cab. All the gears on a shaft must have their teeth perfectly aligned to allow the cab's gears to remain engaged whilst sliding from one gear to the next.

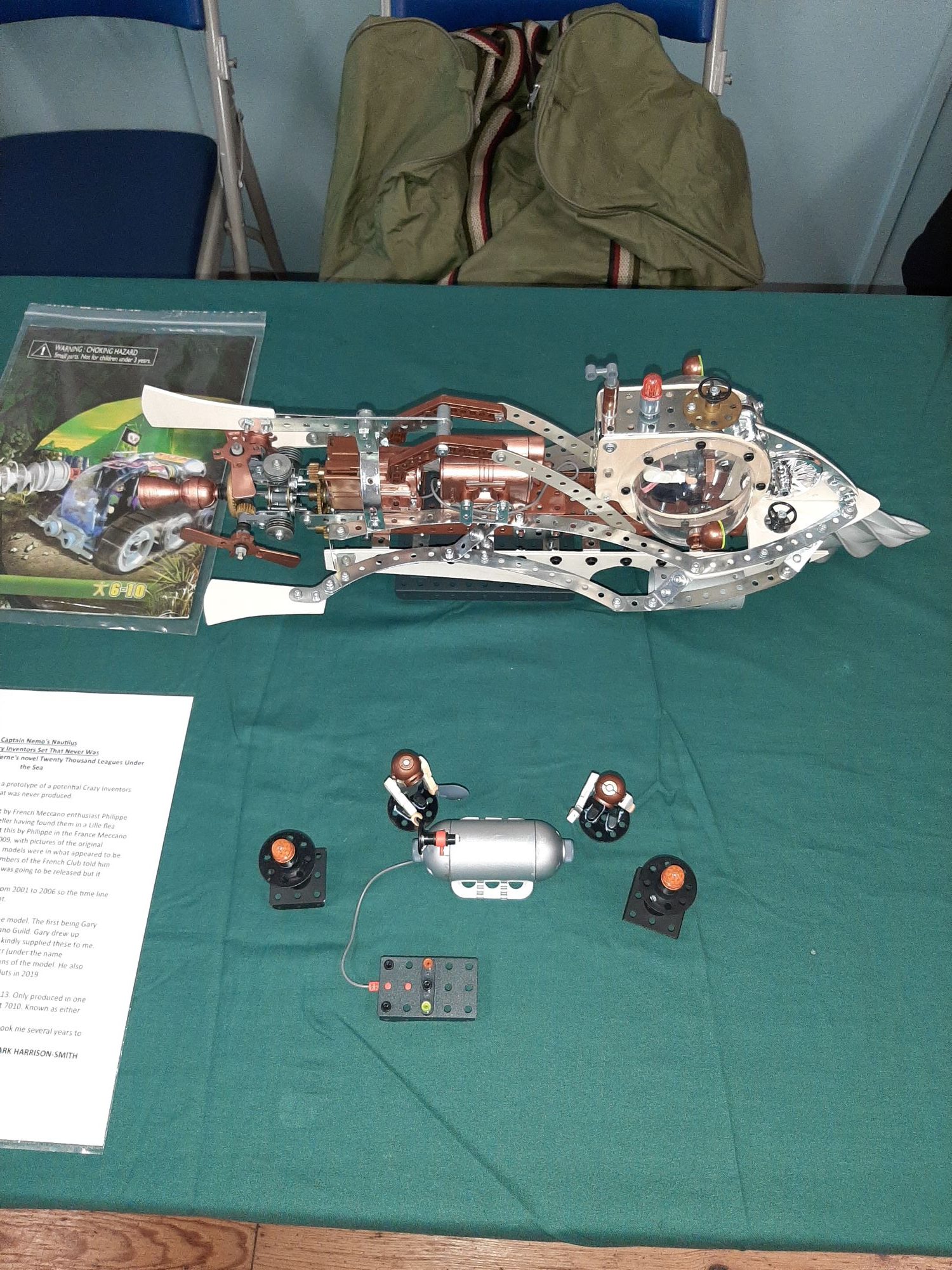

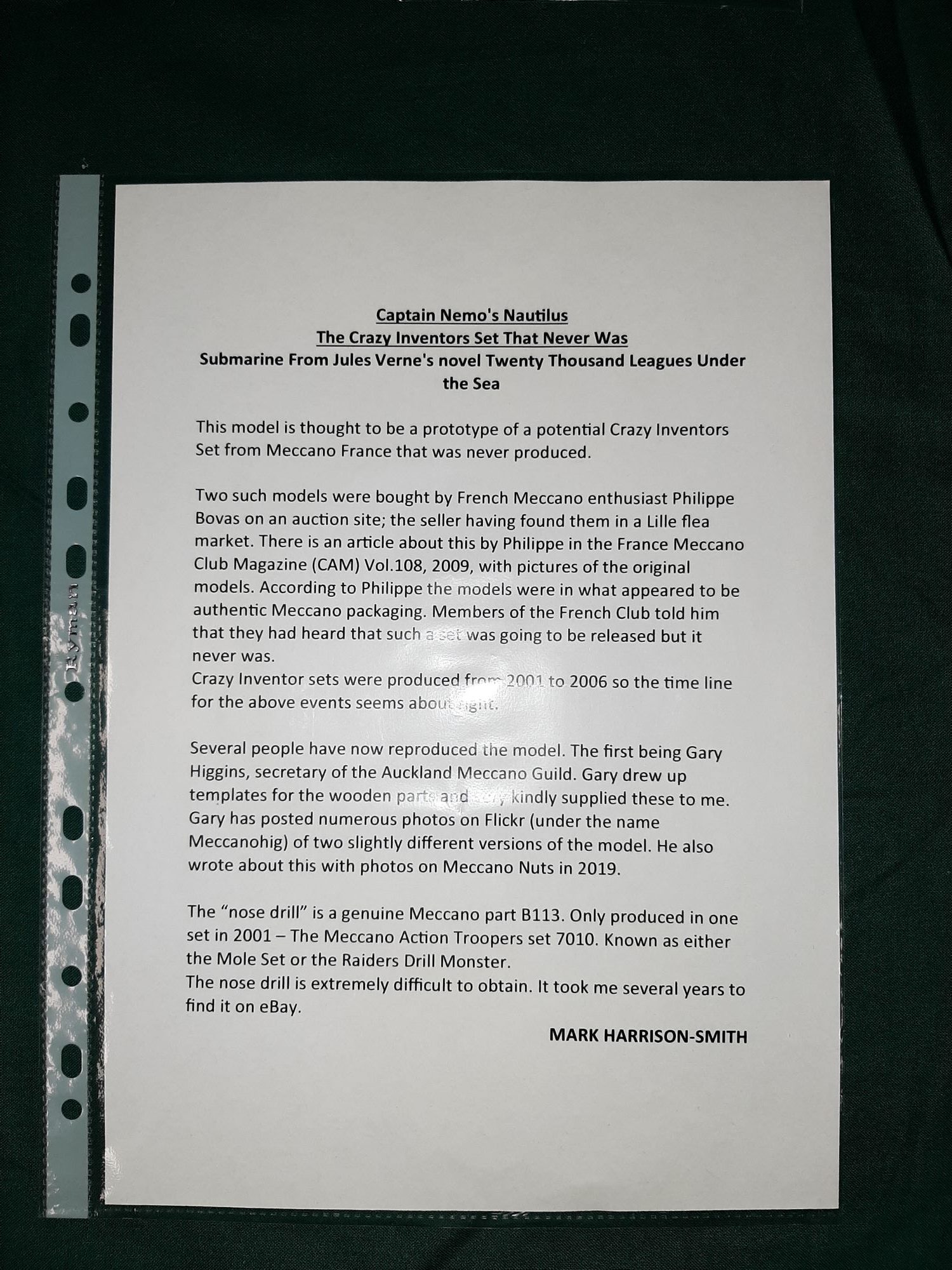

This model of the Nautilus made by Mark H-S was intended to be one of the 'Crazy Inventors' outfits but was only ever made as a prototype for the French market. It was never productionised so is very rare. Mark said two had been found in a French flea market. Within the model there are some 3mm ply parts and the front rubber screw is a Meccano part but extremely rare, found only in some small kits such as the Junior Meccano Action Troopers. More info about this model can be read one of the accompanying photos.

Roger has certainly been busy building. He brought along a crane, a kinetic sculpture, and a tiny drum kit.

His inspiration for the crane came from a 1950's edition of an Eagle comic, which had a cutaway illustration of this German floating crane. The instructions for it are Marklin but it is mostly made from Metallus with some Meccano components. The counterweight might look small but it contains 1Kg of lead. It is approximately 1:88 scale and has a level luffing main hook plus two further hooks, one of which is on a trolley riding up and down the main jib.

The next pictures show the actual crane in action lifting a boat and a fuller description of the history of this type of crane. Of the four built, two sunk, one went to the USSR and one to America, which eventually ended up in the Panama Canal in 1996. In 2023 it was then renamed Titan.

You can read more about this crane in the Wikipedia article about the Panama Titan.

Roger's kinetic sculpture is his take on the one made by Hugo Demarco. Obviously, the sculpture face is not Meccano but it is driven by a sprocket and chain system from the rear. Some of the clearances of the rotating discs to other parts are very minimal and required a little fettling here and there.

The chain was difficult to get working smoothly and still has a slight hiccup now and again. All this was done based on scaled photos taken off the TV.

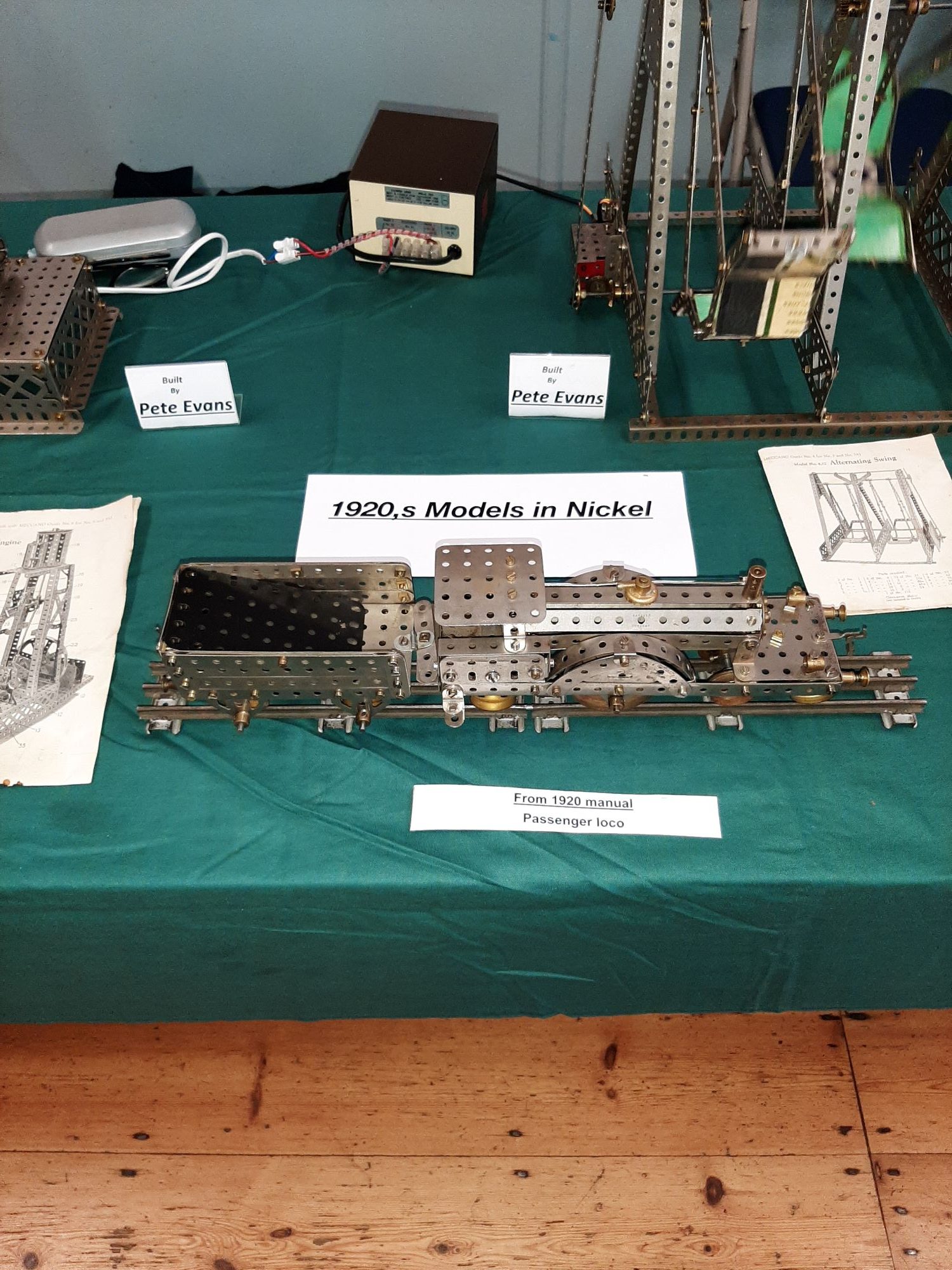

Pete occasionally likes to build in nickel. His display this time was entirely nickel based, starting with a 1926 no 6 set complete with manuals. It is noticeable that prior to 1926 there were no large diameter circular parts.

The locomotive was made from a set 7 and his reciprocating engine was made from a set 6.

More from Pete included a nickel field gun and a motorbike with side car from a set 7. The motorbike won the Ben Johnson Trophy for the best small model as voted for by all members present at this meeting. This trophy will be presented at the January meeting.

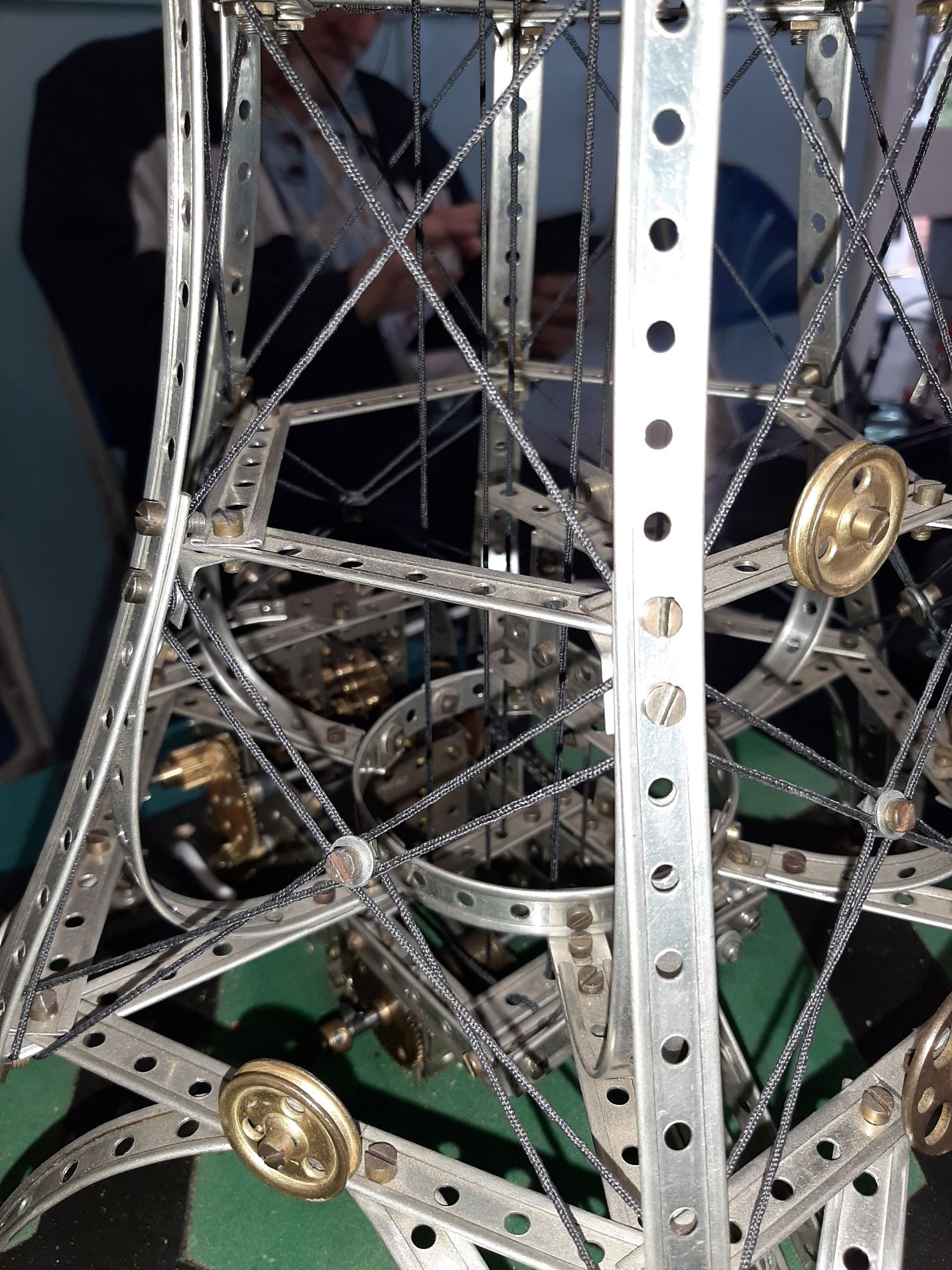

The largest model Pete brought was of a tower constructed by the late Tony Knowles using replica 'Mechanics Made Easy' strips. A fuller description can be read in the photo that follows.

Pete added an auto reverse mechanism but the method of attachment of gears to a shaft in those days used a spring clip wedged into a groove. These clips disengage easily preventing this mechanism from working.

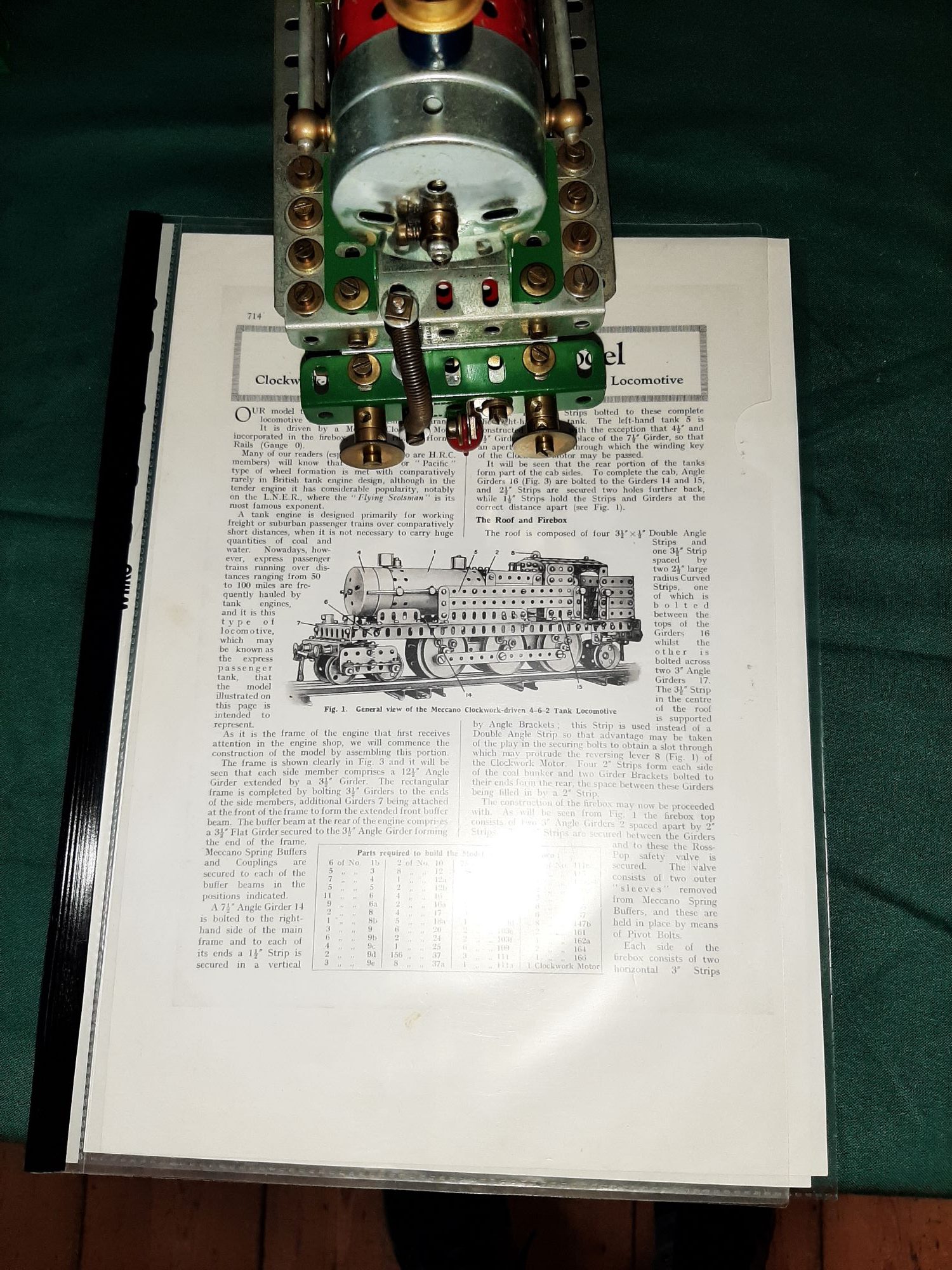

Philip gave his campervan and loco plus bridge another outing. The bridge looks eye-catching in the green and white colour scheme. For the campervan he blew up some diagrams to a scale that matched the available wheel sizes. More information about the loco can be seen on Philip's page.

Steve's strange looking machine is progressing slowly as he hasn't had much time for Meccano building. Some of the other features such as the doors have been prototyped and the cladding around the central core is in place. These features have all yet to be painted in their final colour which means dismantling and rebuild. It all takes time!

This crane in 50's red/green by Kevin D is mainly from a set 9 manual plan but with a different base and turntable. This is a work in progress and he did try powering it from a clockwork motor within the base. However, this did not work properly, so he will try again with the motor in the jib.

Hugh's tractor is from the 1968 November issue of Meccano Magazine. This has been fitted with a functioning hole boring attachment but something within the mechanism is slipping, so a little adjustment is needed somewhere.

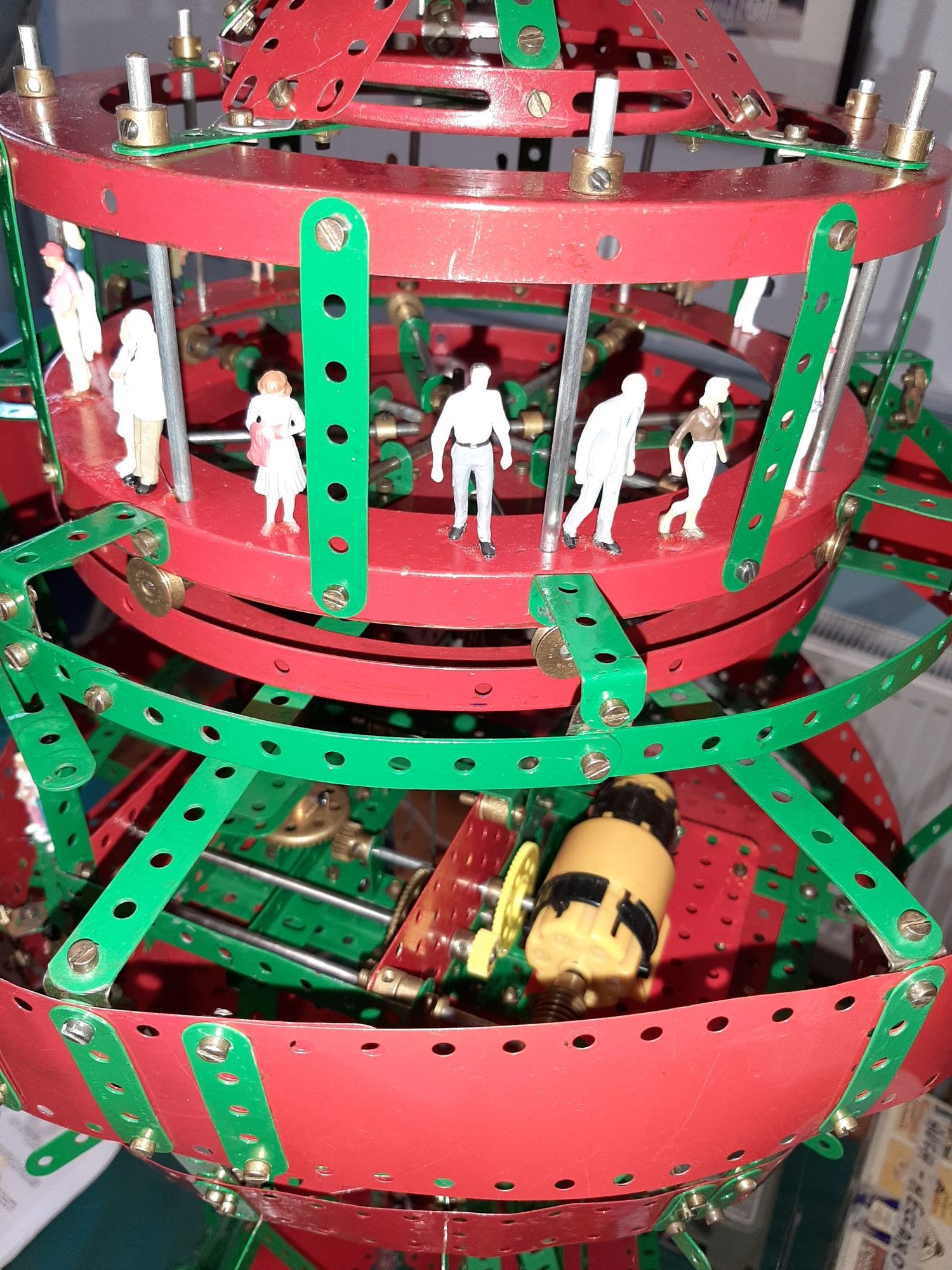

His Seattle Space Needle now has a working lift and a revolving restaurant driven by a Powerdrive motor. This model is a 'collapsed' representation as a full height scale model would be through the roof of the hall! It is not from any plan, but is scratch built working from photos.